Faster, Reliable, and Cost-Efficient

TECHNOLOGY MADE AFFORDABLE FOR YOUR MANUFACTURING PROCESS

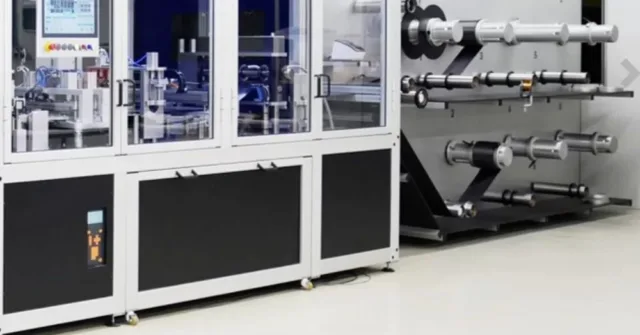

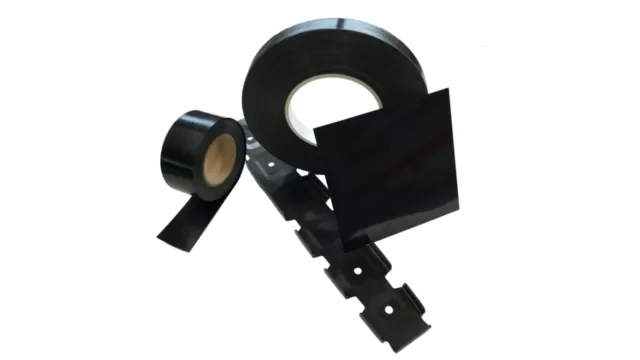

Introducing FALKO, the game-changer in thermoplastic composites. Say goodbye to high costs and hello to lightweight and durable solutions. FALKO revolutionizes the production process by transforming UD tape into semi-finished products, ready for consolidation. With cutting-edge technologies like automated quality control, slitting, automated tape laying, automated seam welding and continuous ultrasonic welding, we deliver reliability, precision, and cost-efficiency.

Reliable, Lightweight Thermoplastic Composites

LIGHTER THAN EVER YET EXTREMELY DURABLE

Until recently, the application of thermoplastic composites was a costly matter. With the introduction of FALKO Technologies, that concern is a thing of the past. FALKO transforms UD tape into semi-finished products suitable for any pre-existing consolidation processes. The result is both lightweight and extremely durable, and can be moulded into a wide variety of premium products and components. FALKO makes the production process with UD tape easier and more reliable.

Breaking New Ground

INNOVATIVE YET PROVEN TECHNOLOGIES FOR A NEW GENERATION

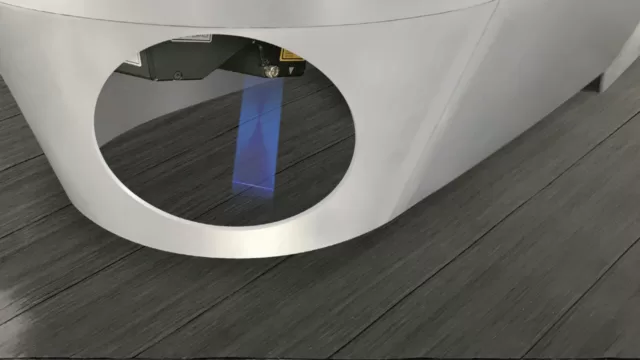

FALKO has been developed through years of research and experimentation with a variety of technologies. Eventually, we decided on a combination of slitting, automated tape laying (ATL) and automated seam welding (ASW) based on ultrasound and pneumatic preforming. Through this process, UD tapes are cut into smaller strips and subsequently welded together without interruption (continuously). A unique and ground-breaking innovation.

Reliable

MULTI-LAYERED, PRECISE AND COMPLETELY SECURE

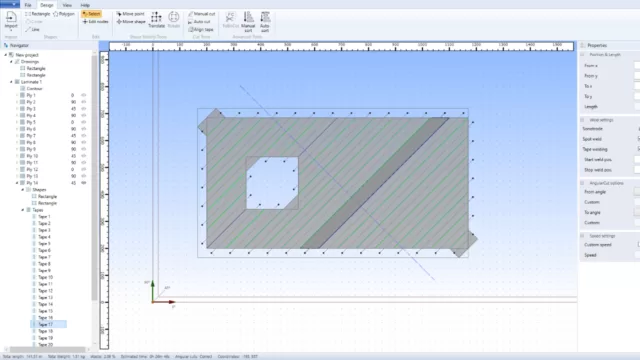

Various technologies are combined in order to guarantee the highest quality laminates. Through slitting, any defects and imperfections in the UD tape are removed and prepared for tape laying. Advanced FalkoCAD CAD/CAM software decides on the optimal placement strategy. A real-time gap verification system verifies the position of every individual UD tape during the production process. The highly efficient ultrasonic welding technology improves the reliability of the process, guaranteeing the quality of the final product.

Affordable

COST-EFFICIENT, HIGH PRODUCTION RATE AND MASS-MANUFACTURABILITY

Cost-efficiency is another advantage of the applied technologies. When it comes to the valuable materials, there is barely any spillage. Outages are reduced to a minimum as well, thanks to the real-time gap verification system. The ultrasonic welding technology reduces the processing time and enables reparation and corrective measures during production. With a production capacity of up to 450 m2 per hour, depending on the material and the configuration) FALKO is ready to mass-manufacture your thermoplastic composite components, recouping your investment costs in no time.

Superior Properties

LIGHTWEIGHT, BUT PACKS A PUNCH

The FALKO produces large-scale and complex thermoplastic composite laminates and near-net-shape products at a superior quality. Compared to traditional materials, it is extremely light-weight yet exceptionally strong, impact-resistant and not subject to corrosion. In addition, the material is weldable, leading to a stark reduction in costs. The absence of rivet holes means construction becomes more durable too. All these properties make for significant advantages and new opportunities.

Infinite Possibilities

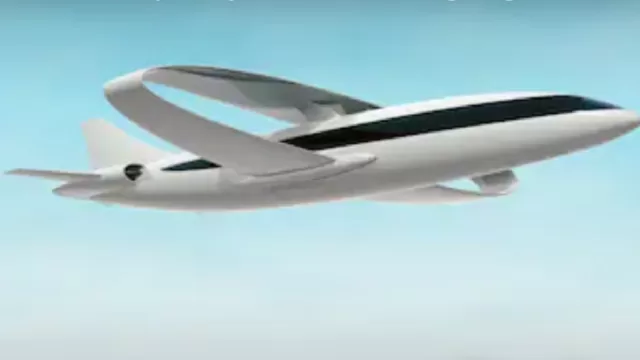

DISCOVER HOW FALKO IS WIDELY APPLICABLE FOR A NEW GENERATION OF PRODUCTS

Working with FALKO thermoplastic composite machines means a never-ending flow of possibilities. The material is not only used to create lightweight components for cars and aircrafts, but also has its place in the production of next-generation wind turbine blades, hockey sticks and tennis rackets. What opportunity does FALKO offer your organisation?

Focus on the Future

THE NEW STANDARD FOR A BETTER WORLD

FALKO introduces new technologies to offer you new opportunities for development. We do our work with the world of tomorrow in mind. With FALKO, processing thermoplastic composites becomes energy-efficient and highly sustainable through the use of 100% recyclable materials, resulting in a lower carbon footprint for your product. In addition, a lighter aircraft or vehicle uses less fuel and has a lower CO2 emission. The products of the future, produced today by FALKO.

The superior properties of thermoplastic composites

Processing next-gen thermoplastic composites, suitable for any production process.

GET IN TOUCH